Copper ore is divided into sulfide ore (oxidation rate less than 10%), oxidized ore (oxidation rate greater than 30%) and mixed ore (oxidation rate 10%-30%) According to the different oxidation rates. the cooer ore beneficiation method is mainly with flotation method. and some with gravity method. In general, copper sulfide ore and easy-t-select mixed copper ore are treated by flotation. For difficult-to-select mixed copper ore and difficult-to-select copper oxide ore, use hydrometallurgy or flotation and hydrometallurgy combined methods.

Applied material : Natural Copper, Chalcopyrite, Chalcocite, Tetrahedrite, Chalcocite, Malachite, Etc.

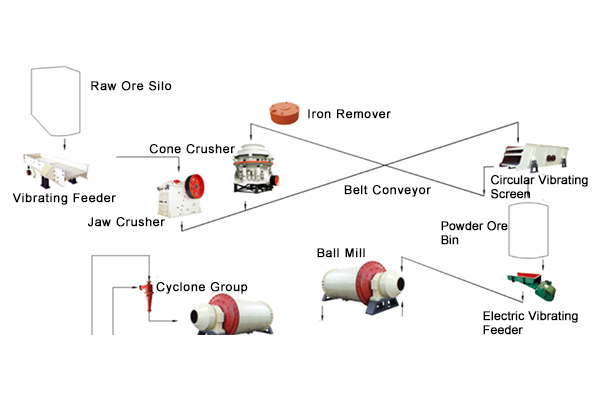

Copper Processing Flow : The process flow is Crushing — Screening — Grinding — Concentration.